There’s broad consensus in the infrastructure and asset management industry that decarbonisation is essential. Around 70% of global carbon emissions are generated by the construction centre. As JPMorgan observes, "buildings are the largest contributor to global warming". Simply reducing 20% of embodied energy consumption in the built environment would save 200,000kg of carbon each year.

Because of this, the industry is starting to look at decarbonisation: reducing the carbon footprint of planned and existing buildings by measures such as using more efficient and environmentally sustainable materials, recycling materials, using lower-emission construction machinery and managing existing buildings more efficiently in terms of energy and water use.

Carbon neutral property is the future of real estate but not enough progress is being made in getting there. KPMG observes in its 2022 Emerging Trends in Infrastructure report that "people have lost patience with talk; they are hankering for action". Politicians failed to achieve consensus at COP 26 or agree on practical goals, but the negotiations at least reinforced the direction for policy makers.

Other initiatives in the sector are also stepping up the pressure, such as the Institution of Civil Engineers’ Carbon Project. Individual organisations are setting their own ambitious targets. Consumer awareness and demand for sustainability is also escalating: from the products people buy to their investment choices. Sustainable investing set records in 2021, with REITs (real estate investment trusts) increasingly adopting ESG principles.

Where all the carbon is coming from

While the majority of emissions are generated in the construction phase (approximately 54%), a significant quantity comes from maintenance and refurbishment (20%), as well as operational energy and water use (23%).

The type of building materials used can be significant in their carbon cost. Concrete cladding has a significantly higher carbon cost than weatherboard, aluminium or steel. For asset managers, short-term savings in cheaper, less carbon efficient materials in construction and maintenance/repair may be more costly in the long-term.

Transparency and data in the construction process is key. The provenance and nature of materials is vital both to ensure sustainability as well as to enable asset managers to plan more accurately.

Turning words into action

Currently, cost and speed still trump quality and sustainability when it comes to Australia’s construction sector. According to the Federal Government’s Building Confidence report, many high rise buildings are now constructed too quickly, with compliance often side-lined, to maximise profits:

"The quality of buildings depends heavily on the competency and integrity of builders. There are many builders that have high standards of competency and integrity. However, the rates of disputes, alleged defects and reports of high levels of illegal phoenix activity are evidence that there are shortcomings in the performance of some builders. These need to be addressed."

The NSW government report into Sydney’s Opal Tower also reveals that lower-quality materials were a key cause of structural problems, with "uncertainty" in the project’s documentation over what strength concrete was actually specified and used.

Material traceability and more responsible material sourcing is a win-win not just for decarbonisation and the move towards net zero, but also for asset managers when it comes to planning. Knowing what materials are used in construction leads to much better understanding of what maintenance will be required and future-proof buildings. It also makes it easier for insurers to more accurately price risk.

Decarbonising existing buildings

Existing assets are unlikely to ever be as environmentally friendly as new buildings, but reducing their carbon footprint through retrofit and refurbishment is still significantly more sustainable than knocking down and building new.

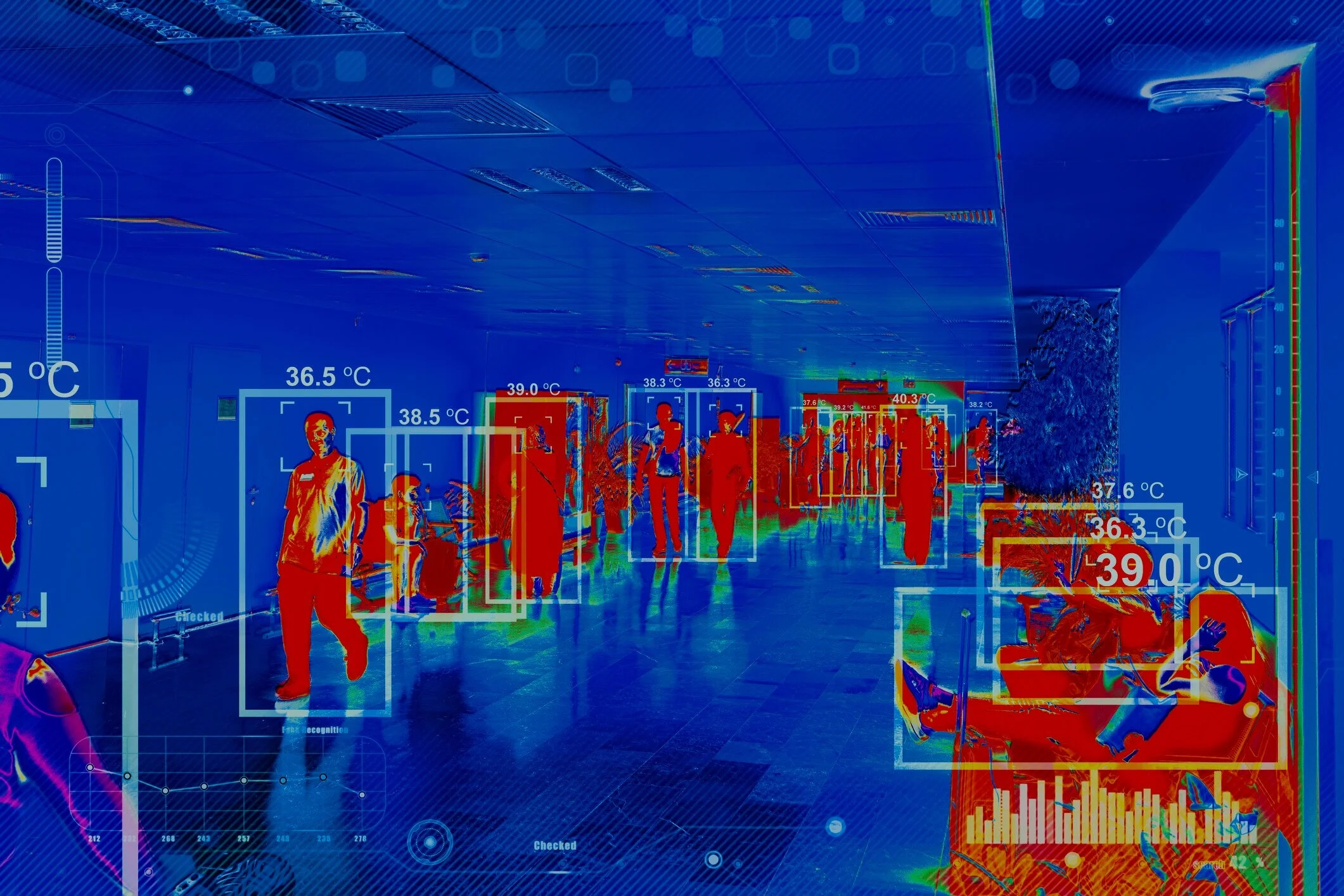

Improving energy efficiency through technology that analyses and optimise energy usage. For example adjusting HVAC systems based on real-time data about occupancy, as well as improving insulation, ventilation and biodiversity.

Increasing renewable energy supply with investment in solar panels and choice of utility provider.

Reducing embodied carbon by assessing the impact of construction materials used for repair/upgrading, reusing old concrete and combining it with timber and aluminium.

Making new assets more sustainable or old assets more resilient can ultimately improve bottom line results. But there needs to be a collective shift in mindset in the construction industry, with asset managers playing a key role in ensuring the assets they manage are sustainable and of high quality. Such assets will gain a competitive advantage in the long-term, being more attractive to tenants and having a lower risk and liability profile.